Understanding the Role of Tonnage in Punching Parts

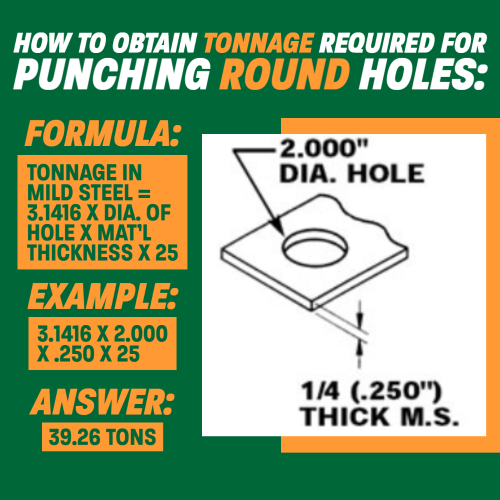

When punching holes in metal, having the correct press tonnage is important. Too little force results in incomplete punches or excessive tool wear. Understanding how to calculate the tonnage required per hole will lead to longer tool life and improve the punching process. The required force depends on: A simple formula estimates the force needed: Tonnage= (Perimeter × Thickness × Shear Strength) ÷ 2000 Example: Punching a 1-inch hole in ¼-inch mild steel (50,000 PSI shear strength): (3.14 × 1″) × 0.25″ × 50,000 ÷ 2000 = 19.6 tons UniPunch recommends using up to 60% of your press tonnage. In this case, a 34 ton press or more would be ideal. For a quick and accurate calculation, use UniPunch’s Tonnage Calculator. ✅ Choose the right tooling – UniPunch tooling is designed to maximize efficiency with minimal tonnage. Need help selecting the right tooling? Contact UniPunch today!

What Determines Tonnage?

✔ Material type – Harder materials like stainless steel need more force than aluminum.

✔ Material thickness – Thicker materials require higher tonnage.

✔ Hole size and shape – Larger or more complex shapes increase force requirements.

✔ Die clearance – Proper clearance reduces force needed and improves hole quality.

How to Calculate Tonnage

Optimizing Tonnage for Better Performance

✅ Use specialty punches – Chisel shear, back-taper, or heeled punches can reduce required force.

✅ Maintain sharp tooling – Dull punches increase force needs and shorten tool life.