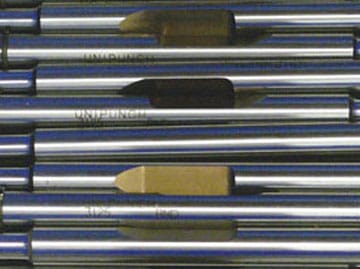

About UniPunch UniPunch is in Business to Help Manufacturers Speed Up Their Operations Using Modular C-frame Press Tooling

Application Engineering / Tailored Designs

“UniPunch offers a streamlined solution to boost factory throughput, and our dedicated design team is here to support you every step of the way. When you send us a part drawing, our experienced team leverages our extensive 100 years of combined experience and our unique library of past projects to assess your requirements. Based on our analysis, we recommend the most suitable tooling option for your specific part and application. At UniPunch, we pride ourselves on our wide range of standard components readily available off-the-shelf, thanks to our large inventory. However, we understand that certain customer parts may require modifications. In such cases, UniPunch excels at customizing standard components to meet your specific needs. By combining tailored designs with readily available components, we can provide you with the ideal tooling solution for your new application. We are excited to assist you in achieving optimal results.

History

In 1955 a group of innovative engineers started UniPunch in Niagara Falls, New York with what was then a new concept to more efficiently produce the punches used in the modular bump dies known as “C-frame,” or “unitized” tooling. Before long UniPunch was manufacturing a complete product line and offering the application expertise to assist customers in choosing the right unitized tooling for their particular needs, for example a dedicated setup to produce small batches of a recurring part or tooling for a relatively large quantity of a prototype that might only be produced once.

UniPunch continued with a spirit of innovation and became the world’s largest manufacturer of unitized tooling. Then in 1999, we purchased the Strippit and Pierce-All unitized tooling product lines.

As more and more manufacturers saw the advantages of small lot sizes and the need for fast set up times, UniPunch responded by providing new mounting systems that let manufacturers quickly change from one part to another. Indeed, UniPunch customers report they can changeover in less than a minute. Another customer created a video that is one minute, thirty-two seconds long and is allowing us to share it with you here.

In 2022, UniPunch and Unittool joined forces. This initiative merged the product offering, sales channels and manufacturing to efficiently serve the entire marketplace with both brands from a single location.

Locations / Sales and Service Support

Now UniPunch Products has its world headquarters in Amery, Wisconsin where we manufacture and distribute from a large inventory.

7 Reasons to Use UniPunch

What UniPunch offers is speed other technologies can’t match. Here are seven ways we outpace the other guys when it comes to punching holes in extruded or shaped parts.

How It Works

Learn how UniPunch tooling works, what you need to get started with our tooling and how the equipment can make the unique design you need.

History

In 1955 a group of innovative engineers started UniPunch in Niagara Falls, New York with what was then a new concept to more efficiently produce the punches used in the modular bump dies known as “C-frame,” or “unitized” tooling.

Testimonials

In the six decades and counting we’ve been in business, we’ve helped thousands of clients realize faster production. View a few of their stories.

Applications

A variety of manufacturers use UniPunch systems for their production. See a comprehensive list of industries we’ve worked with in the past.

Media Gallery

UniPunch has numerous instructional videos, charts and images to help you get a better understanding of our unique technology.