Create Hole Patterns With UniPunch Tooling

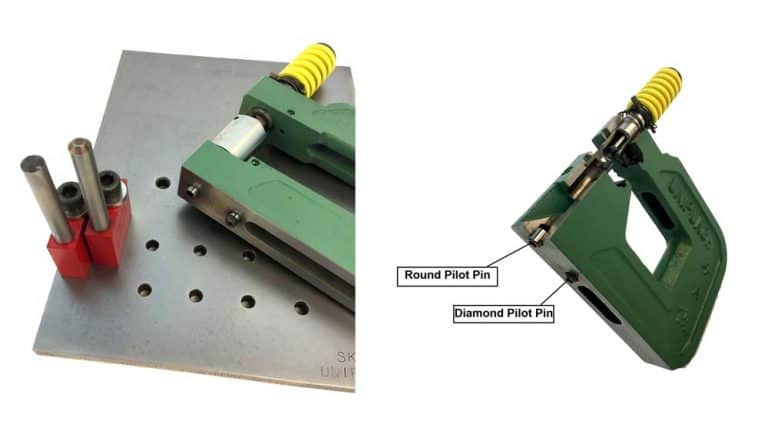

Are you looking to streamline your hole punching and part notching processes? Look no further than UniPunch. Our innovative tooling system offers a range of units that can be used together to create precise hole patterns and edge notches, making the production of parts faster and more efficient. The UniPunch system is designed to simplify the creation of hole patterns. With its c-frame casting and precisely aligned punch and die, you can achieve accurate results. The key to creating the desired hole pattern is the round pilot pin located at the bottom of the unit. By inserting it into the designated hole in the mounting system, such as a mounting template, you can easily achieve the desired outcome. But what if you require a shaped hole? UniPunch has got you covered. An additional diamond pilot pin, also known as an orientation pin, maintains the orientation of the shape within the hole pattern. This ensures consistency across multiple batches of parts. The UniPunch system empowers you to create complex hole patterns without sacrificing accuracy or efficiency. The UniPunch system offers a host of advantages that can significantly enhance your manufacturing processes. Its ability to create precise hole patterns, combined with its rapid setup time and increased production speed, make it a game-changer for businesses aiming to improve efficiency and productivity. Whether you are looking to streamline your existing operations or stay ahead of the competition, UniPunch can help you achieve your goals. Say goodbye to tedious setups and hello to a more efficient and productive future.Create a Hole Pattern in Parts

Embrace UniPunch for Enhanced Efficiency