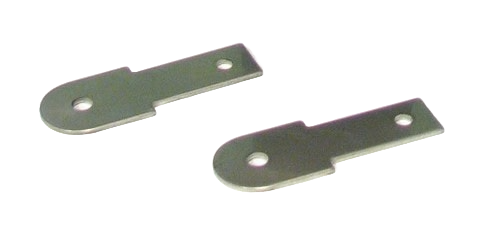

Custom Hole Punch Designs

When it comes to cutting precise shapes out of metal, UniPunch custom hole punch designs provide an efficient and cost-effective solution. Blanking is the process of cutting a desired shape out of a flat piece of sheet metal. UniPunch tooling is used when the punch slug serves as the blank itself. Interestingly, a well-made punched hole has two sizes: the size of the punch on the entry side and the size of the die on the other side of the material. In blanking, it is the size of the blank that is crucial. The blanking die is made to size, while the punch is intentionally undersized to provide the appropriate punch and die clearance. UniPunch designs ensure accurate and consistent blanking results, meeting the exact shape and size requirements of your application. This precision eliminates the need for additional machining processes, saving time and reducing costs. UniPunch understands that every application is unique. Their team of experts works closely with customers to develop custom tooling solutions, taking into account specific material thicknesses, hole sizes, die clearance, and production requirements. UniPunch’s lower-cost alternative to traditional die sets significantly reduces tooling costs, making it an attractive option for small part production or combined blanking and punching operations. Additionally, UniPunch’s efficient tooling systems minimize material waste, further enhancing cost savings. UniPunch’s turn-key systems simplify the blanking process, from setup to production. With integrated mounting systems and gauging, their solutions enhance productivity and minimize downtime between operations.What is Blanking?

Benefits of UniPunch Custom Hole Punch Designs

Precision and Efficiency:

Customization:

Cost Savings:

Streamlined Operations: