Looking for a Faster Alternative to Drilling Holes?

How UniPunch Speed Helps You:

Faster Production Speed

More holes in more parts per hour. If you’re finishing 400 parts in a day now, imagine 2,400 instead.

Faster Into Production

We can provide most UniPunch tooling within days, so there’s no need for you to wait months.

Faster Setup Time

Faster changeover from part to part.

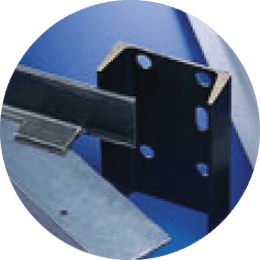

A Manufacturer of garage storage systems significantly increased production with UniPunch.

The Challenge

“Drilling holes became too slow for us. Rhino Shelf is a fast-growing, high-quality company and product. We are committed to being American-made and holding ourselves to the highest standards of quality and performance. UniPunch seemed to share that commitment, so we reached out to them to create custom tooling for our parts.”

Working with UniPunch

“The entire process with UniPunch was excellent, from the first time we contacted them through delivery of the tooling. UniPunch’s team was FAST, EFFICIENT, and PROFESSIONAL. UniPunch’s communication was excellent. Drafts of our tooling were done quickly. We refined the drafts and, once finalized, the UniPunch system arrived at our facility. Setup for Unipunch was easy with our press brake.”

Speeding up Production

“Once we put UniPunch to work, we knew that we made the right decision. We can punch parts TEN TIMES faster than drilling. Before UniPunch, we had an extensive deburring process. That has now been eliminated. Most importantly, Unipunch is extremely SAFE. Our employees are the best and their safety is more important than any other function of the company. Drill presses can be unsafe in several ways, but our punching process is BY FAR the safer option.”

The Tooling Pays for Itself

“Safer, faster, more efficient. By our calculations, each setup pays for itself in 14 weeks.”

“We have now transitioned our most common parts to UniPunch tooling exclusively and, due to the excellent results that we’ve achieved, will be transitioning ALL of our parts quickly.”

“I want to thank Howard Stream and the entire UniPunch team for their attention to detail, their fantastic service, and their product that has revolutionized the way we manufacture Rhino Shelf – the best garage storage shelving ever made.”

Aaron B. Carter

Innovative Design Technologies, LLC

Tell Us About Your Job and We’ll Help You Make Holes Fast!

Our experts have helped thousands of manufacturers increase their speed of production.

Call us at 1-(800)-828-7061 or fill out the form below, and our team will recommend the right UniPunch solution for your needs.

Manufacturers Love Saving Time with UniPunch

Here is what just a few of them had to say:

“When I came in, they didn’t know about UniPunch. It used to take them three weeks to complete 300 locks…now we’re making 600 in one week just because I knew about the UniPunch system and was able to teach them how to use it and pick up our production.”

– Lock Set and Door Hardware Manufacturer

“The operators like working with the tooling. Once it’s set up and you have your template made, it’s a breeze…just a snap.”

– Dave,

Engineering Manager

The Metalworking Group

“Without costing an arm and a leg, there is just no other way to do it. The labor would be outrageous.”

– Tim,

Tooling Designer

Cooper B-Line

Frequently Asked Questions

How fast can UniPunch send tooling to me?

Fast—often within days. The nice thing about modular UniPunch tooling is that it’s available off the shelf, so even if a project needs some customization, you can still be in production quickly.

Can Unipunch make more than one hole at a time?

Absolutely! This is just one of the ways that production with UniPunch can be so much faster.

What materials can be punched with UniPunch?

UniPunch is commonly used on mild steel, stainless steel, A36, aluminum, copper, brass, composite materials, fiberglass, plastic, and rubber.

What kind of shapes can UniPunch make?

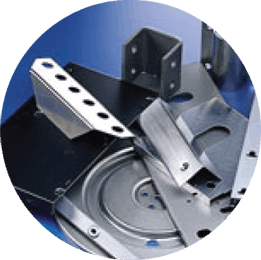

While UniPunch can be customized for almost any shape, here are some of the most common shapes.

Hasn’t C-Punch Technology Like UniPunch Been Around for Decades?

Absolutely — it’s tried and true, and still the best, fastest way to make holes in extruded or shaped metal.

How do I know which UniPunch tooling I need?

That’s what our experts are here for. Give us a call at 1-(800)-828-7061 or fill out the form above and we’ll recommend the right setup.

Download the Getting Started PDF.

Some of the Most Common UniPunch Applications

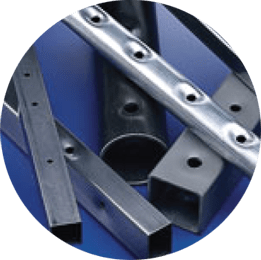

Aluminum Extrusions

- Ladders

- Door sills

- Window Frames

- Computer Racks

- Truck Trailer Components

Formed Parts

- Roll Formed

- Brake Formed

Structural Parts

- Angles

- Channels

- I Beams

Tubing & Pipe

- Round

- Rectangular

- Shaped Holes

- Round Holes

- Coping