AH Series Units for Punching 1/2″ Thick Mild Steel

AH Series Overview

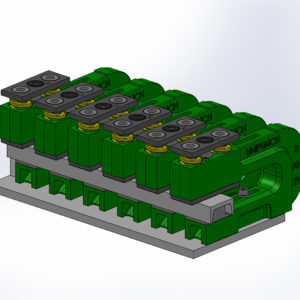

Heavy Duty Hole Punching Units with Standard 8 3/8″ Shut Height and 3 1/2″ Die Height

Designed to punch thick structural parts, these units are used to put holes in C channel, I-beams, heavy angle iron and more.

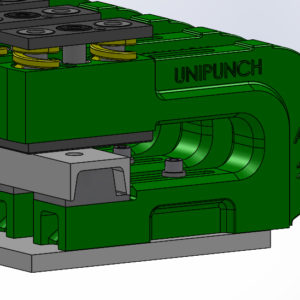

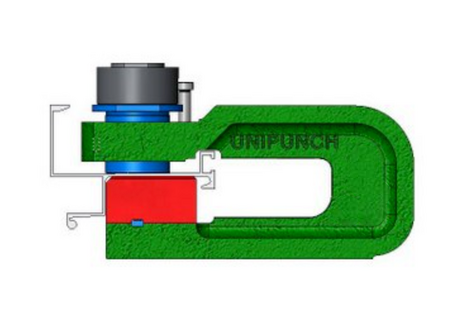

“AH” series punching units offer tooling that can punch up to 1/2″ thick mild steel. Available “AH” series holder widths are: 2 ½”, 3”, 3 ½” and 6”. Holder width is important because it defines the minimum hole to hole distance. Depending on your material thickness, punch diameters are available from .2500” (6.35mm) to 3.000” (76.20mm). This series can punch up to a 3” diameter hole in 1/4″ mild steel and up to a 1.500” diameter hole in 1/2″ mild steel. The “AH” series features multiple heavy duty springs in order to strip punches from mild steel as thick as 1/2”. Hardened steel bushings provide long life and accurate rigid alignment of punches.

In addition to a wide range of standard round and shaped punches and dies, UniPunch provides punch and die pairs in shapes custom made to your specifications. The “AH” series is available with holder throat depths of 8” and 12”, which means the center of the hole can be that distance from the edge of the sheet.

UniPunch units are rugged holders that allow you to punch burr-free holes with minimal maintenance. Various mounting methods are available including dedicated templates for fast changeover at the press.

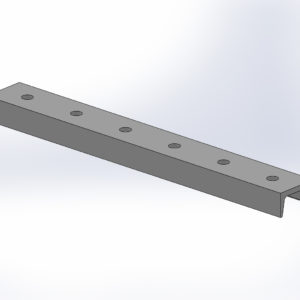

For applications where holes are required near the legs of angles or extrusions, UniPunch can provide block style dies in AH and A Series units. The block die can also provide the required front to back part gauging.

The UniPunch engineering team will design a tooling setup specifically for your punching project. Send us a part drawing today!