Stripping Spring Units

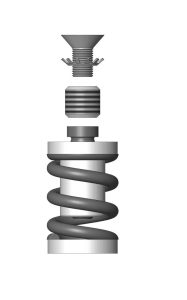

Stripping Spring Units (SSUs) are compact, self-contained units consisting of a spring compressed in a retainer which is telescopic and non-revolving. With exact, standardized stripping pressures they strip work and scrap from dies (blanking, forming, under-turning or returning cam slides).

Design your die with EASY maintenance in mind!

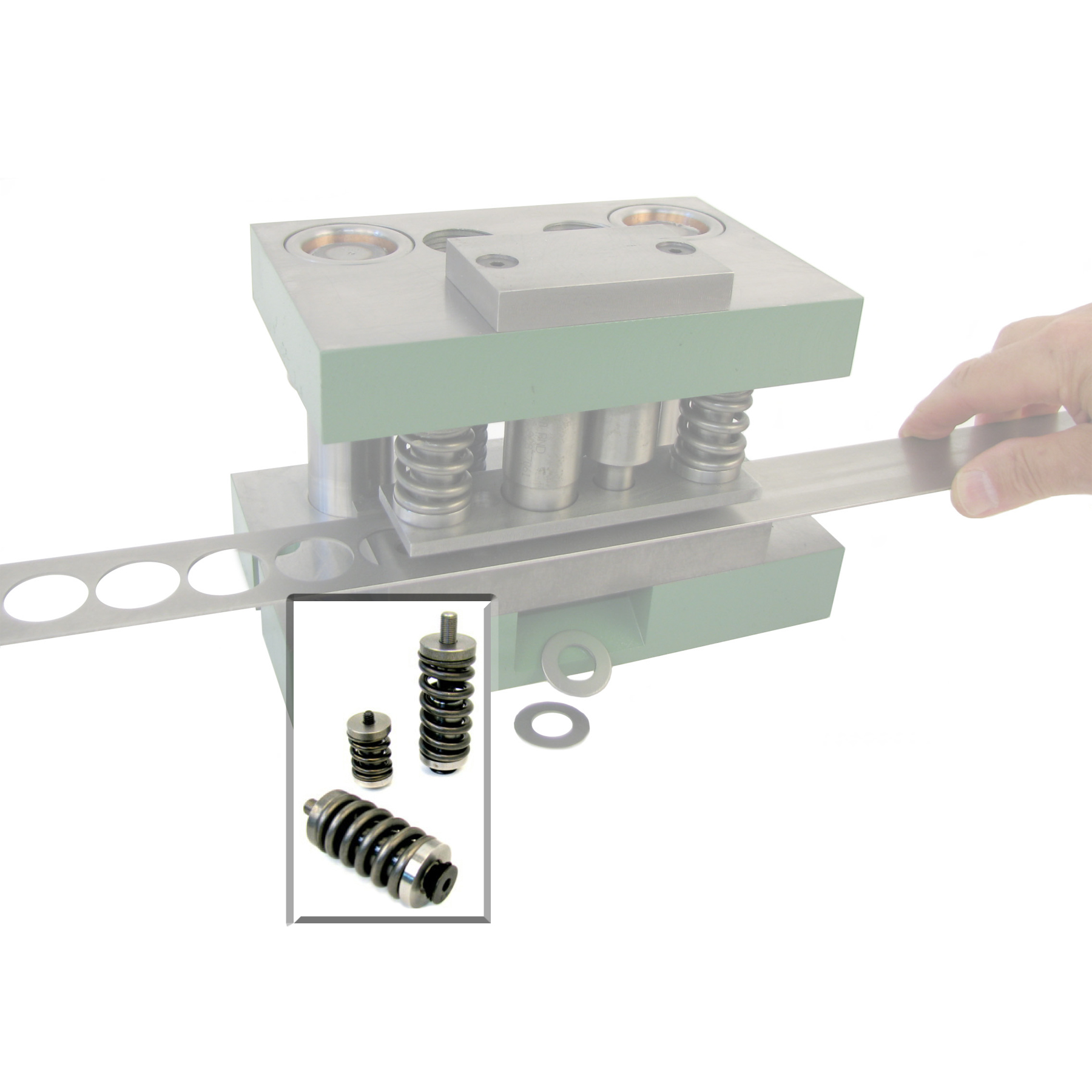

UniPunch SSUs are used in die sets as strippers, lifters and in some cases in place of a stripper plate.

Benefits of Stripping Spring Units:

- Minimize die design problems

- Uniform stripping pressure

- Relieve die maintenance/press downtime found with conventional stripping springs

*To obtain the full benefit from Stripping Spring Units, dies should be designed especially for their use.

Minimize Dies Design Problems…

Stripping Spring Units are factory assembled with a uniform preload which standardize stripping pressures and ensure uniform stripping action. This eliminates the problem of calculating and designing stripping mechanisms. Dies designed specifically to use Stripping Spring Units are invariably more compact, less complicated and much more economical to produce.

SSUs are easily installed which saves hours in die making. All machining is done from the face side. Drill and tap a hole where a SSU is needed; spot-face a surface around the hole and install the SSU (all spot-facings must be equal depth).

When using SSUs, the stripper plate does not need to be as thick as with conventional springs since they are a self-contained unit that exerts no pressure on the stripper plate until it makes contact with the part.

To install SSUs in an existing die that uses conventional springs, simply close the stripper bolt holes with threaded plugs, then drill and tap for the SSUs.

Relieves Die Maintenance/Press Downtime Found with Conventional Stripping Springs

Stripping Spring Units help eliminate a major production problem that is often caused by flying debris and unequal pressure when a conventional spring breaks. The SSU is designed with a sleeve between the stripper bolt and the spring. The spring fits tightly around the sleeve to help contain shrapnel of the spring if it were to break.

Depending on the die design, when dies are equipped with SSUs; it may only be necessary to remove the stripper plate screws, remove the plate and replace the SSUs.

Uniform Stripping Pressure

Stripping Spring Units eliminate uneven stripping pressures caused by varying lengths of screws and depths of counter bored holes. SSUs are factory pre-assembled at equal lengths to ensure uniform stripping pressure. Equally spaced SSUs provide an even stripping action over the entire stripper plate regardless of how many SSUs are required.

SSUs are available in several uniform sizes that can be stacked to provide the length required.

Get Started Today & Contact Us About Your Job.

Our experts have helped thousands of manufacturers increase their speed of production. Speak to our experts with decades of experience working with manufacturers and machine shops like yours. See how you can achieve greater efficiency with our stripping spring units.

For any questions, call us at 1-(800)-828-7061 or fill out the form below.