Punch Aluminum Extrusions

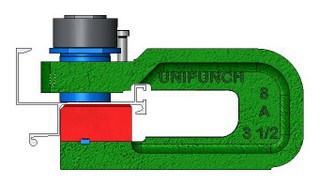

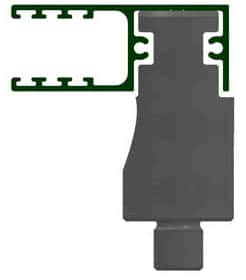

UniPunch tooling is commonly used for punching holes in aluminum extrusions up to 1/4″ thick. While many of our clients use our standard tooling to punch extrusions, UniPunch frequently modifies the pedestal die and/or holder to accommodate special shaped parts.

UniPunch has several types of tooling that are suited for punching the unusual shape of extrusions and will help you select the right tooling for your job. Feed Clearance Units and “AJ” Series are ideal for punching holes in aluminum extrusions. They feature a pedestal style die for punching close to the leg of an extrusion.

“Using UniPunch pedestal dies is the only way we can punch holes in these complicated extrusions. We have tried many other things before, but this is the best way.”

-Libio Ramirez,

Ultra Industries

- Window Extrusions

- Metal Buildings

- Lighting

- Seating

- Interior and Exterior Doors

- Seating

- Appliances

- Furniture

- Storage Systems

- Shelving

- Cabinetry

- Trailer Extrusions

- Marine

- Lift Gates

- Truck Beds

- Fencing/Animal Enclosures

- Feeders

- Radiators

- Tractors

- Combines

Contact UniPunch for more information on punching aluminum extrusions.