Efficiency Unleashed: Cost-Savings with UniPunch Tooling

Seamless Integration into Existing Processes

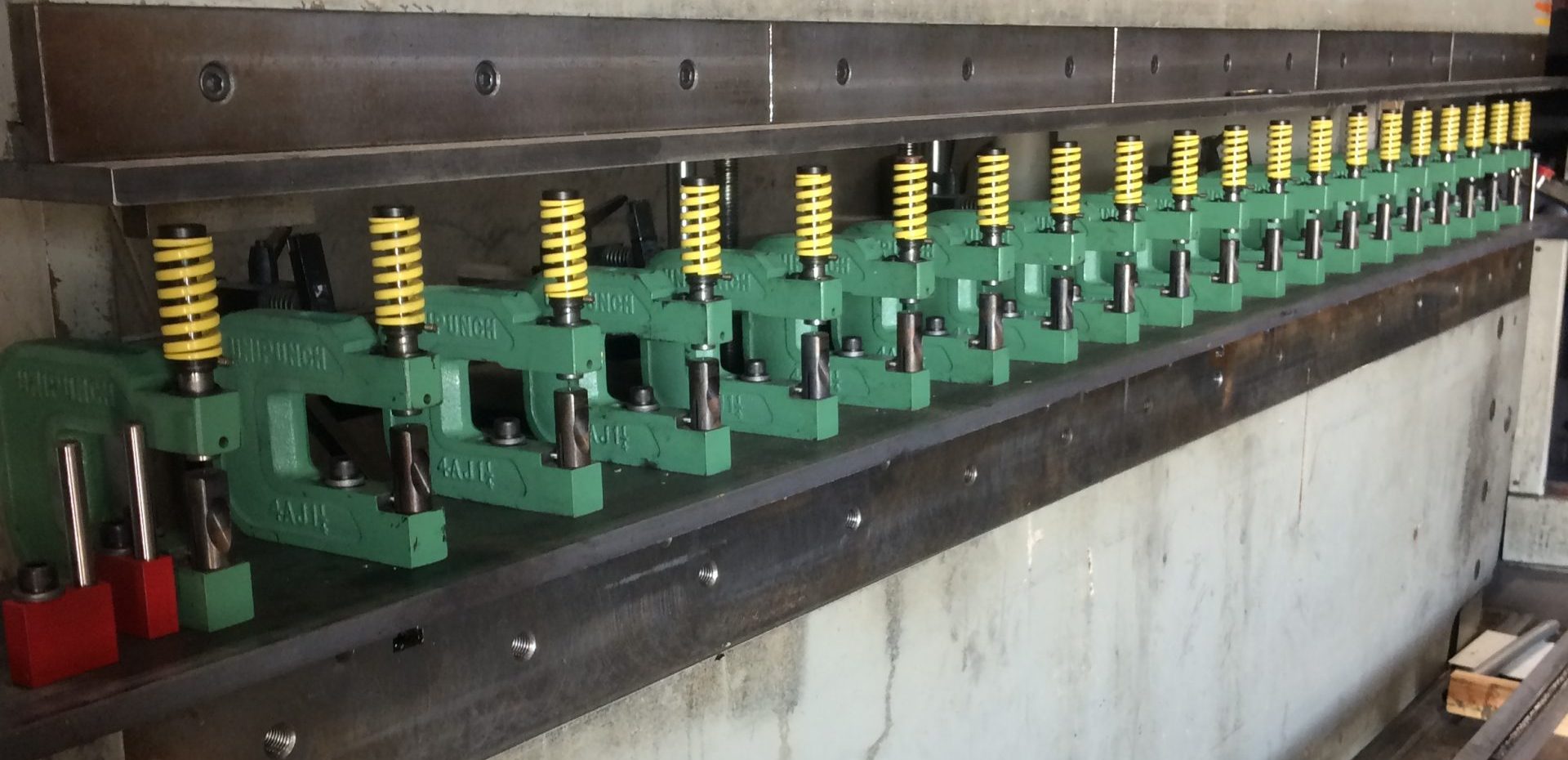

UniPunch tooling solutions are engineered to seamlessly blend into existing manufacturing setups, enhancing efficiency without the need for complete overhauls. Our systems can adapt to various production environments, ensuring a smooth transition and immediate improvement in setup and production times.

Customer Triumphs and Tangible Returns

Our clients, from Special Purpose Vehicles Manufacturers to High-Quality Lock Sets producers, have documented remarkable savings and productivity gains. For instance, one manufacturer halved their steel inventory, saving $5 million annually and doubling output. These success stories underline not just cost savings but also the strategic advantage of moving to Just-In-Time manufacturing. The typical return on investment (ROI) for UniPunch tooling is compelling, with many customers seeing significant operational savings that quickly offset the initial investment, often within months.

Customization Meets Manufacturing Needs

UniPunch tooling is incredibly versatile. Whether it’s adapting to specific materials or unique part configurations, our tooling is designed to meet your precise manufacturing needs. This customization helps you put holes in small intricate parts and heavy channel. Our team designs turn-key tooling systems to meet your hole punching needs.

The Future with UniPunch: Efficiency and Flexibility

Running UniPunch tooling isn’t just about enhancing current operations; it’s about minimizing waste and keeping production flexible. With UniPunch, you’re not just choosing a punching system but selecting a partner dedicated to providing the fastest and most efficient ways to punch and notch parts.

By integrating UniPunch tooling, you’re streamlining your production and boosting your efficiency.