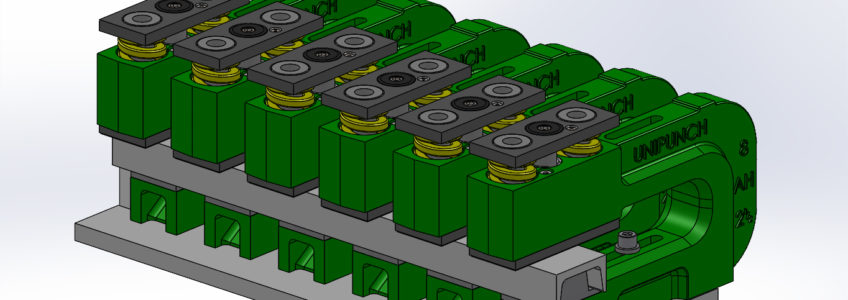

Avoid Drawbacks of Die Sets: Why UniPunch Systems Are a Better Choice

When it comes to punching multiple holes in extrusions, die sets and UniPunch systems can seem similar at first glance. Both methods allow for precise, multi-hole punching, but the differences between them become apparent when considering lead times, maintenance, and upfront costs. Here’s why UniPunch systems offer significant advantages over traditional die sets.

Lead Times

One of the biggest drawbacks of die sets is the long lead time. Each die set is custom-made, and that process can take an average of six weeks—or sometimes even longer—before it arrives at your facility. In contrast, the typical lead time for a UniPunch system is only one week. With UniPunch, your production process won’t be left waiting for weeks on end, allowing you to start working on your project much faster.

Maintenance

Die sets require disassembly for maintenance, causing production delays. UniPunch simplifies the process—punches and dies can be replaced on the shop floor, keeping your operations running smoothly.

Upfront Costs

Investing in die sets comes with a hefty upfront cost, especially when compared to UniPunch tooling. UniPunch systems are designed to be versatile and modular, making them a more cost-effective solution that still delivers precision and efficiency. If your design changes, UniPunch units can be rearranged with minimal effort and cost.

For a faster, more efficient, and cost-effective solution, choose UniPunch. Contact us at 800-828-7061 or info@unipunch.com to learn more.