Installing and Operating UniPunch Tooling with Your Existing Equipment

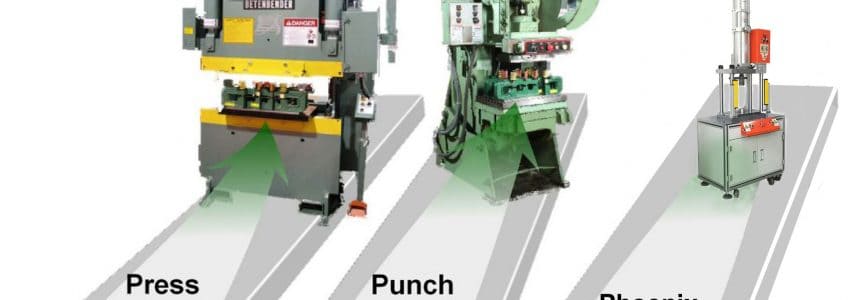

You don’t need new machinery to boost production speed and efficiency. UniPunch tooling integrates easily with your existing press brake or punch press, turning your current setup into a high-efficiency system. Here’s how easy it is to get started.

Installing UniPunch Tooling

UniPunch tooling is designed for easy installation on your existing equipment. Simply mount the units using strip templates, bed rails, or T-slotted plates, and you’re ready to go. The modular design allows you to punch multiple holes in one stroke, significantly cutting down production time.

Operate with Speed and Precision

Once installed, UniPunch tooling is simple to operate. It’s self-stripping, so punches retract automatically after each stroke, reducing manual effort. For recurring jobs, quick changeovers ensure you can switch between tasks with minimal downtime, keeping your production line moving efficiently.

Maintain for Long-Term Use

Routine maintenance is key for long-term performance. Regularly inspect punches and dies for wear and replace as needed. UniPunch tooling is made from high-quality tool steel, ensuring it stands up to high-volume use.

Why UniPunch?

By integrating UniPunch tooling into your current equipment, you’ll improve production speed, accuracy, and reduce setup times. UniPunch allows you to produce more parts in less time, lowering your production costs without the need for major investments.