Punch Manufacturing Tools

Our punch manufacturing solutions increase throughput, reduce bottlenecks and frequently save clients significant money upfront. Because our tooling systems are simple to use and easy to learn, it's also easy to train individuals on their use. For these reasons, customers around the world have made us their go-to punching tools manufacturer. The UniPunch team is available to customize tooling to fit your specifications. We'll happily and quickly assess your hole-punching needs. Then we'll recommend tooling solutions to fit your unique application.

Here are some examples of designs using standard and/or custom components including:

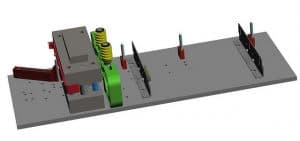

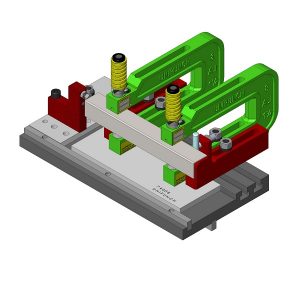

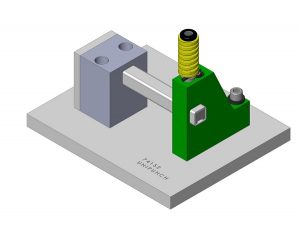

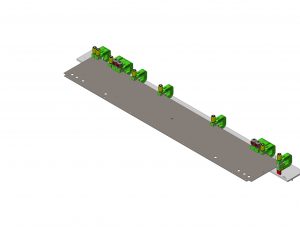

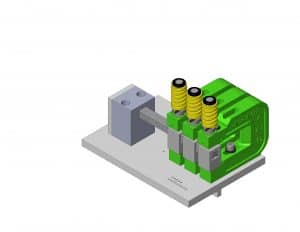

- Systems to punch multiple holes in one hit

- Mounting and gauging (part positioning) systems for multiple part applications

- Die Sets for use alongside our standard tooling

- Systems to fit with customers’ press specifications

- Progressive tooling solutions

- Tooling solutions to fit your coil fed systems

Contact us to get started.

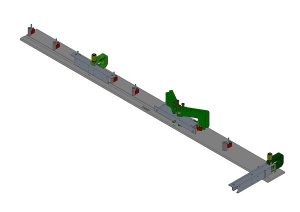

Progressive Setup for Blanking

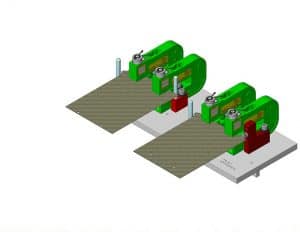

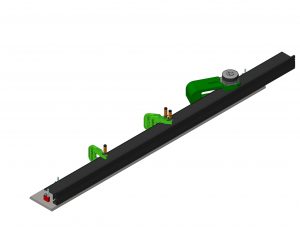

Dedicated Mandrel Tube Punching Setup on Template

Dedicated Mandrel Tube Punching Setup on Template