Tooling System Capabilities

How You Can Use UniPunch

Built for Versatility in Metal Fabrication

UniPunch tooling systems support a broad range of metal fabrication processes—all designed to boost productivity and reduce setup times. Whether you’re punching holes, forming, or notching, our modular tooling can handle everything from simple round holes to complex formed features.

Common applications include:

-

Hole Punching – Precise round and shaped holes from .0937″ to 3.000″

-

Notching & Trimming – Edge work and part shaping in a single setup

-

Extruding & Forming – Create flanges, louvers, embosses, and countersinks

-

Tube Punching with Mandrel – Accurate holes in round and square tubing

-

Electrical Knockouts & Keyholes – Fast, repeatable results for industry-standard patterns

Our systems are used across industries to punch and form parts faster—with accuracy and repeatability that streamline your workflow.

Contact us to get started.

Typical Parts & Materials

Adaptable to Various Components

Our systems efficiently handle:

- Parts & Shapes: Extrusions, structural components, formed parts, tubing, flat sheets, plastic sheets, and composite materials. We offer custom and standard shapes to meet unique requirements.

- Materials: Aluminum extrusions, mild steel, stainless steel, A36 steel, copper, brass, composites, laminates, rubber, and fiberglass.

Using the Phoenix Press System to Activate Tooling

For shops without an existing press, UniPunch recommends the Phoenix Air Over Oil System—a compact, cost-effective, and ready-to-use solution for punching operations. The Phoenix Press is ideal for dedicated setups and small production runs, delivering the same speed and precision UniPunch tooling is known for.

Real-World Applications and Setups

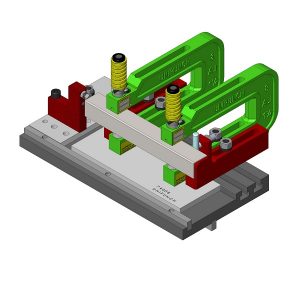

Dedicated Setup for Notching Corners and Punching a Hole

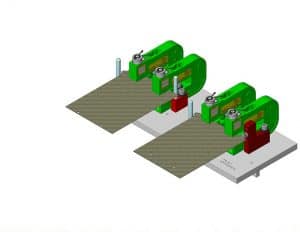

Progressive Setup for Blanking

Dedicated Setup Using Strip Template

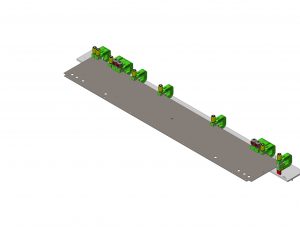

Multiple Dedicated Setups for Multiple Holes on One Template

Punch Many Holes in One Hit with a Dedicated Setup

Multiple Hole Air Over Oil Turnkey System

Tandem Unit to punch close hole-to-hole centers

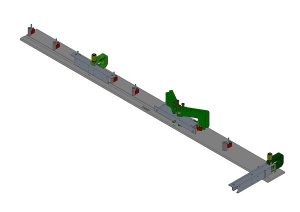

Horizontal Tube Punching System

Hit and Flip Dedicated Setup on Template

Dedicated Setup on Template

Dedicated System for Odd Shaped Parts

Linear Rail UniPunch Turnkey System

Send us a quote request, we’ll review your needs right away.

We’ll draw upon our combined 100 years of experience and our unique library of past projects to recommend the tooling option best suited for you.

Include details like part material type and thickness; press tonnage and open height.