Forming

How Does UniPunch Tooling Punch and Form Metal?

UniPunch tooling is commonly used to punch and form holes in metal, such as countersunk holes and louvers. Punch and form in one hit of the press to eliminate secondary operations. With UniPunch tooling you can punch and form holes in shaped parts, such as aluminum extrusions. UniPunch application engineers will design tooling for your specific part.

Typical Products

- Enclosures

- Furniture

- Storage Racks

- Head Screws

- Shelving

- Hinges

Typical Applications

- Air vent holes

- Holes in sheet metal for tapping

- Recessed holes for flat

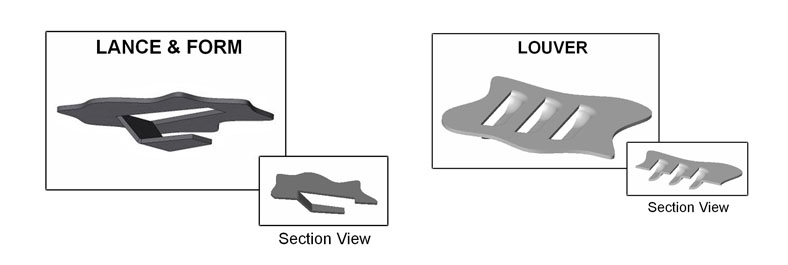

UniPunch designs a wide variety of lance & form tooling. The size, shape and depth of the lance are required for quotation.

Shown here is a pierce and form operation typically for air venting applications.

Send us your drawing showing the required width, height and depth of the louvers.

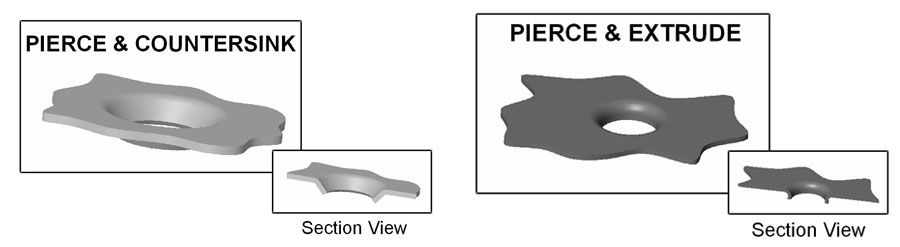

With UniPunch tooling, you can punch and countersink your material in a single press stroke. Send us the screw or fastener dimensions for a tooling quotation.

Another ideal application for UniPunch tooling is the pierced and extruded hole to prepare sheet metal for tapping. To Request a Quote, provide screw sizes and material type and thickness.

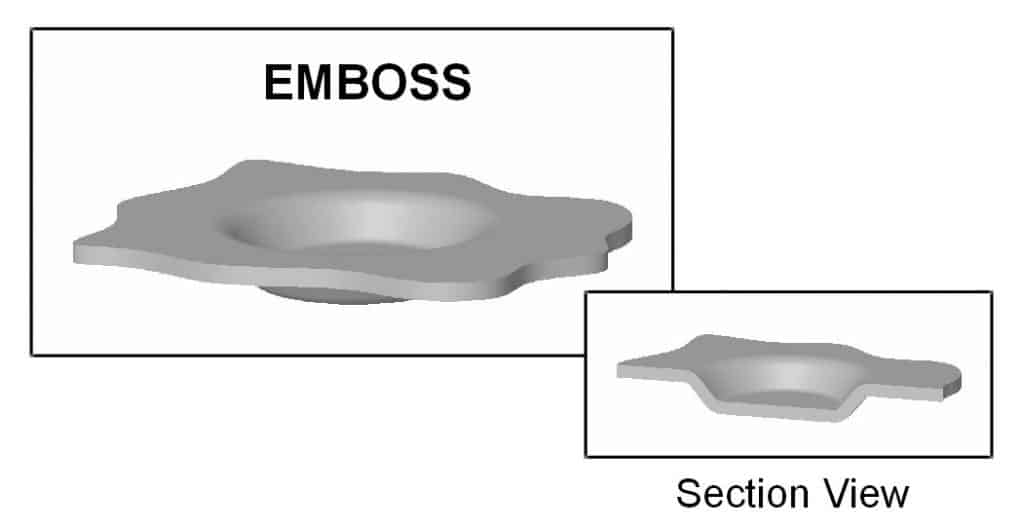

Embossing is a raised or sunken indentation in sheet metal without cutting the material, one of many forming operations that can be done with UniPunch tooling. Provide us with a drawing for a fast quotation.