Metal Blanking

What is Blanking?

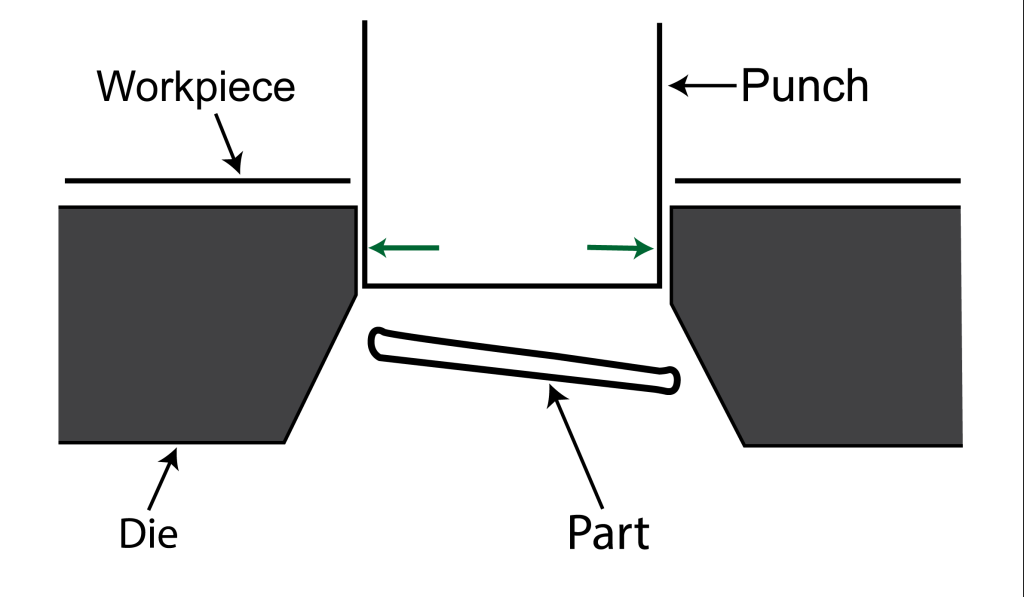

Metal blanking is the process of cutting a desired shape out of a flat piece of sheet metal. UniPunch tooling is used in applications where the punch slug is the blank. Curiously, a well-made punched hole is 2 sizes: On the side where the punch enters, the hole is the size of the punch, and on the other side of the material, the hole is the size of the die. If the size of the hole is important, the punch is made to size, and the die is oversize. In blanking, it is the size of the blank that is important so the blanking die is made to size, and the punch is undersized to provide the appropriate punch and die clearance. The punch is supplied without shear to maintain flatness of the blank.

Custom Blanking Solutions

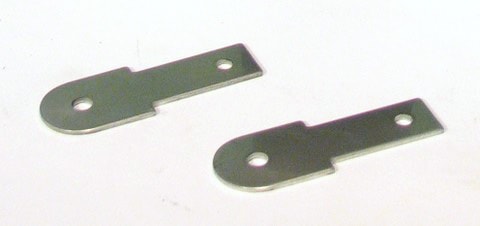

UniPunch provides custom turn-key systems for progressive blanking including the mounting system and gauging. Typical applications include washers, shims, identification tags and nameplates. Compared to a die set, UniPunch tooling is a lower cost alternative for blanking small parts or blanking and punching in the same operation.

Request a quote designed specifically for your application.